Mapping 100% of the unit flow

Ucelo's technical team analyzed 43 pieces of equipment to identify bottlenecks and improve the reliability of the conveyors.

PROBLEMs

The goal of this work was to map 43 conveyors in the soybean preparation and extraction, as well as the bran line and shell/powder system. The focus was on providing data such as equipment capacity, identifying flow issues, evaluating bottleneck equipment, calculating required power, and estimating equipment fill levels. The aim was to develop an action plan, including equipment adjustments and replacements, to increase the unit capacity to 2300 tons per day and optimize the conveyors.

diagnosis

To diagnose and solve the issues, Ucelo performed a mapping of 43 conveyors in two stages:

- Field data collection: External inspection and measurements of structures (boxes, chutes, feet, heads, tails, chutes, and immediate transitions in feed and discharge).

- Internal component analysis: Evaluation of buckets, belts, chains, gears, and other parts.

recommended solutions

Based on the collected data, deficiencies were identified in equipment feed and discharge, as well as the need for standardization and improvements in drive systems.

- Eliminate bottlenecks: Resizing 27 conveyors to meet the established demand.

- Standardization of components: Adopting a standard for 80% of the elevators, reducing stock complexity.

- Increased operational speed: Adjusting motor and gearbox configuration.

- Equipment replacement: Identifying 9 conveyors needing complete replacement.

- Adopting direct-mount gearmotors: Removing intermediate transmissions for greater energy efficiency.

- Monitoring and operational reliability: Identifying reliability losses and operational issues requiring maintenance and inspection. A preventive maintenance plan was recommended to ensure detected field failures are corrected and regularly monitored to maintain equipment performance.

REPLACEMENT OF METALLIC BUCKETS

Metal buckets increase the risk of sparking and subsequent explosion due to suspended dust, making it necessary to replace them with plastic elevator buckets.

LATERAL LEAK IN CONVEYOR BELT

A leak was diagnosed at some points of the conveyor belt, with possible misalignment and some layers coming off, which affects the overall operation of the equipment.

MISALIGNMENT

Misalignments were identified in the elevators, and corrections were recommended.

CONCLUSION

By applying the recommendations from the engineering team, the expected results are:

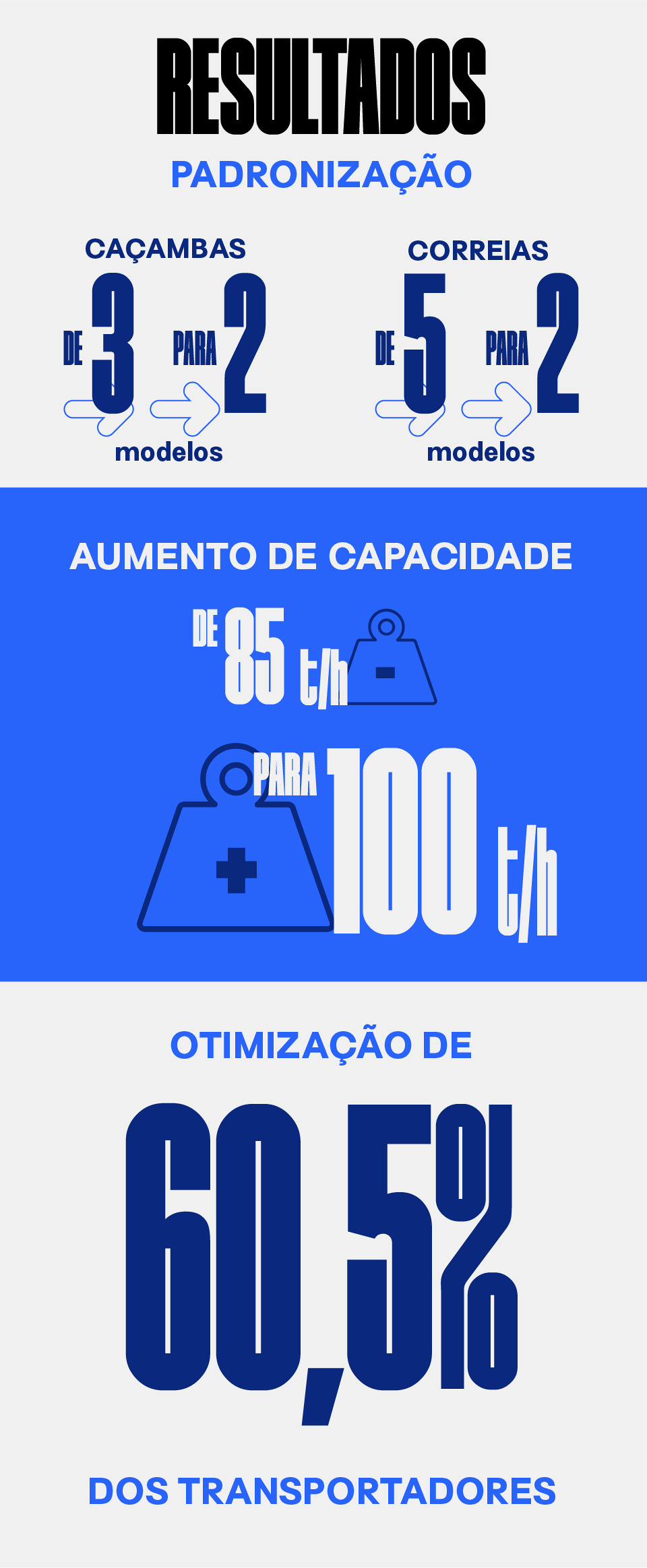

- Performance increase: 60.5% optimization of conveyors to ensure efficient flow.

- Grinding capacity increase: from 85 t/h to 100 t/h, allowing the unit to reach 2,300 t/day.

- Reduced losses and load return: optimization in the feeding and unloading of conveyors.

- Greater standardization: 33.3% uniformity of buckets and 40% of belts, improving inventory management.

- Energy efficiency: replacement of conventional drives with direct motors, reducing operational costs.