Elimination of Product Return

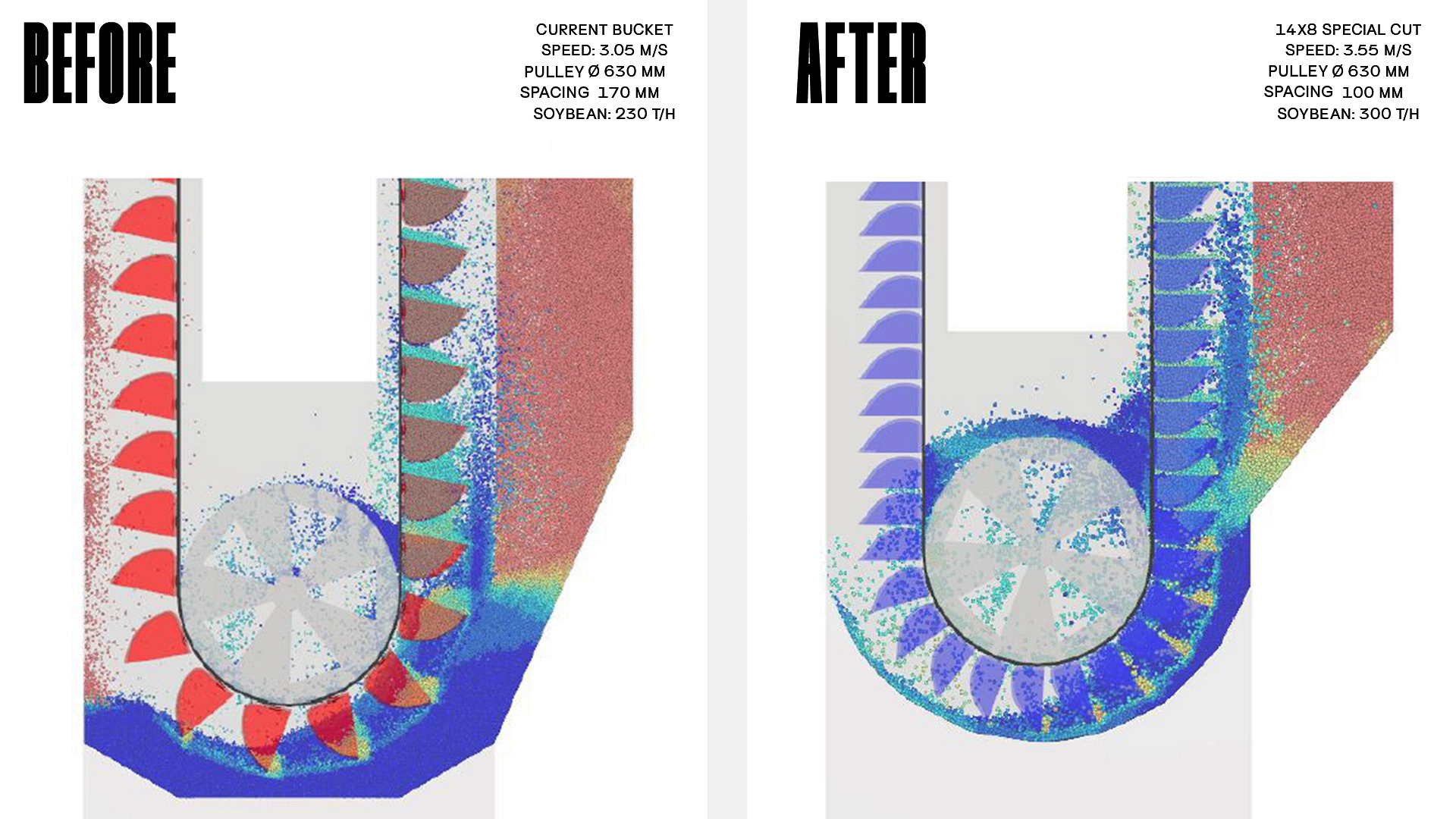

Increase in operational capacity from 230 t/h to 300 t/h.

PROBLEMs

A client from a grain storage facility in Mato Grosso (MT) approached Ucelo for a performance analysis of their bucket elevator. The goal was to identify the best plastic bucket solution and assess the need for structural changes to optimize the grain handling capacity.

The system faced challenges in feeding and discharging soybeans, leading to a high return of load and an increased risk of jamming. The system's capacity was 230 t/h, but with a return of approximately 35 t/h, which compromised operational efficiency.

Diagnosis and Solution

Based on advanced simulations and diagnostic analysis, the Ucelo team identified issues with the layout of the feed chute and the head of the elevator, which directly impacted the equipment's performance.

The following solutions were implemented:

- Replacement of Buckets: Installation of the 14x8 Special PEAD Eagle model, ensuring higher resistance and load capacity.

- Feeding Optimization: Modification of the feed chute to increase the product's arrival speed.

- Redesign of the Elevator Head: Addition of a rolled plate to optimize the discharge flow.

- Recommendation for Drive System Change: It was recommended to replace the drive motor to meet the new 300 t/h capacity.

Results