ZERO BUCKET BREAKAGE

See how Ucelo optimized CHS's soybean and corn storage unit in Bom Jesus (PI), solving bucket breakage issues and improving production efficiency

PROBLEMS

The CHS unit in Bom Jesus (PI) reached out to Ucelo due to significant operational challenges. They faced recurring issues with bucket breakage and inefficient elevator performance. The client's goal was to increase handling capacity to 300t/h and reduce costs associated to unplanned downtime caused by component failures.

DIAGNOSIS AND SOLUTION

The Ucelo team conducted a technical visit to analyze five elevators and five conveyor belts at the unit. Problems identified included elevator misalignment, belts unsuitable for the pulley diameters, and breakage in overlapping buckets due to their advanced projection compared to the others. Additionally, one conveyor belt was installed with the cover side inverted.

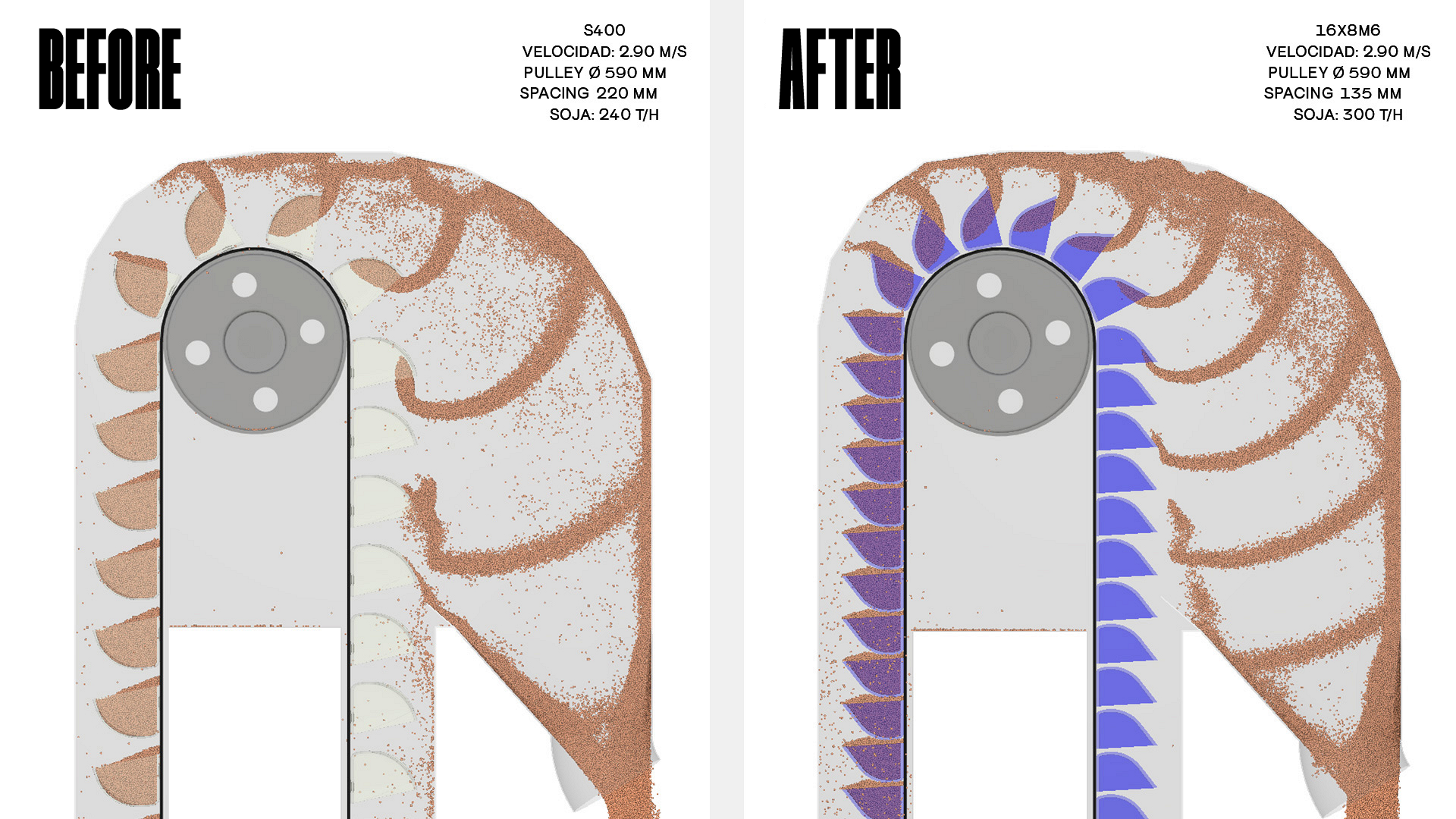

The elevators operated with standard market buckets, 400mm in wide, running at 200 t/h.

The buckets installed in the overlapping joints had a larger projection, causing an overload that led to premature wear and breakage of the components.

To achieve the desired results with full precision, different equipment and component configurations were tested in the virtual laboratory.

As a result, a change in the installed bucket standard was recommended, implementing the industrial 16x8 line in HDPE Eagle to improve product resistance and reliability. Worn-out belts installed with inverted cover sides were replaced and properly sized to prevent unplanned downtime.

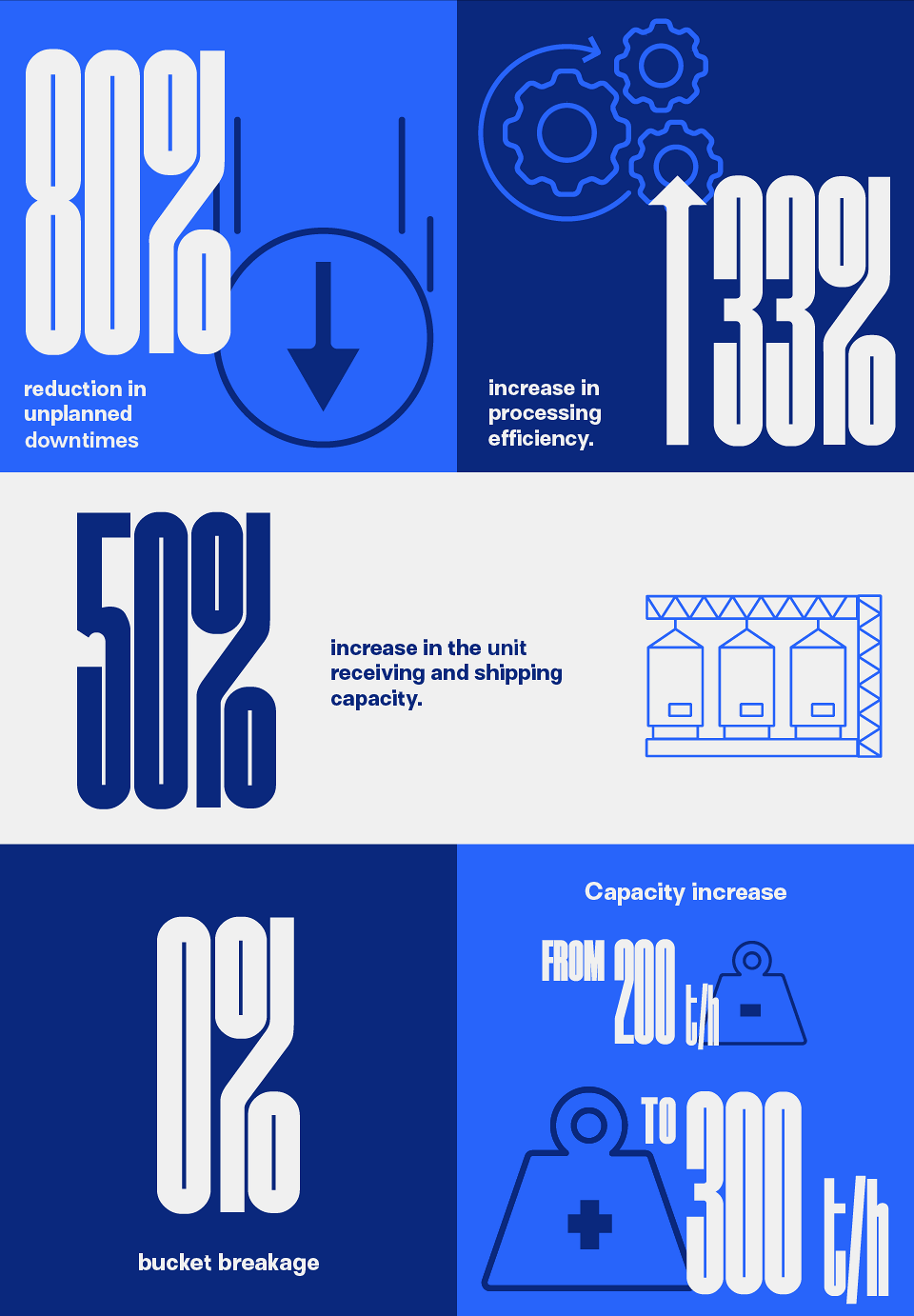

RESULTs

Performance Improvement: The solutions implemented by Ucelo increased operational capacity from 200 t/h to 300 t/h, a 50% boost in the unit’s receiving and shipping capacity.

There was a 33% reduction in loading time required to move the same amount of product.

Increased Lifespan: The replacement of buckets and belts, along with the correction of equipment alignment and sizing, eliminated the need for frequent replacements and unplanned downtime, extending the lifespan of components.

Economic Impact: With increased operational capacity and the elimination of frequent maintenance costs, the unit achieved a significant improvement in efficiency and process reliability. The initial investment was quickly offset by the reduction in unplanned stoppages and the optimization of product handling.

summary

5 BUCKET ELEVATORS

5 CONVEYOR BELTS

PROBLEMS:

Recurring bucket breakage and elevator performance inefficiency.

DIAGNOSIS:

Misalignment of the elevators, belts unsuitable for pulley diameters, and breakage in the overlapping buckets due to their advanced projection compared to the others.

Conveyor belt installed with the cover side inverted.

TECHNICAL IMPLEMENTATION:

Installation of 16x8 industrial buckets in HDPE Eagle.

Proper sizing and installation of the belts.

RESULTS:

80% reduction in unplanned downtime.

33% increase in processing efficiency.

Improved operational time efficiency.

Increased capacity: From 200 t/h to 300 t/h.