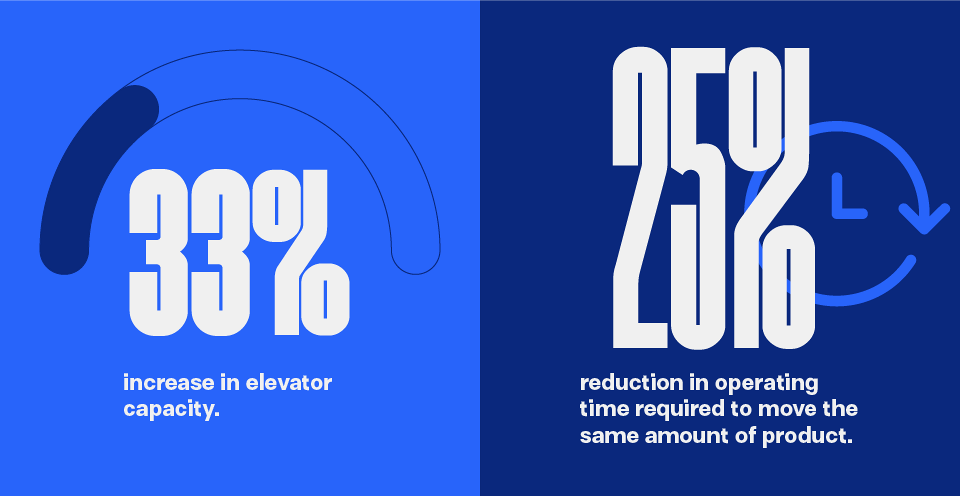

33% capacity increase

With the efficiency improvement, the company achieved a 25% reduction in operational time needed to move the same amount of product

PROBLEMS

Bunge Sapezal (MT) faced a significant challenge: the operational capacity of its unit was no longer sufficient to meet the company's current needs. With increasing demand and the need to optimize soybean movement, the company turned to Ucelo for efficient solutions to enhance productivity.

diagnosis and solution

During the technical visit, 12 equipment were evaluated, including 7 conveyor belts and 5 elevators, where the problems causing inefficiency were diagnosed. The unit’s operational capacity was only reaching 150 t/h, far below the client’s desired capacity of 200 t/h.

After several analyses in our virtual laboratory, where different configurations for the equipment and components were tested, a customized sizing was done, and the replacement of components in the Elevator Kit and drive system was recommended.

The engineering team sized new gearmotors to match the required power and speed for the new capacity of 200 t/h, along with the appropriate belt and bucket kits for this level of movement.

The entire conveyor set was standardized, with the elevators equipped with 11x8 industrial buckets in HDPE Eagle, FO Contitech belts, and two models of gear reducers were selected to meet the needs of all 12 equipments.

RESULTs

Capacity Gain: The implementation of these solutions led to a capacity increase of approximately 33% across all elevators, rising from an average of 150 t/h to 200 t/h.

Time Efficiency: The same amount of product was moved in 75% of the anticipated time, significantly reducing operational and energy costs for the equipment. This represented a 25% reduction in the operational time required to move the same amount of product.

CONCLUSION

The technical intervention carried out by Ucelo at the Bunge unit in Sapezal (MT) not only solved the initial problem of underutilized capacity but also resulted in a significant increase in productivity and operational efficiency. The standardization and modernization of the equipment enabled our client to achieve a higher level of performance, directly resulting in resource optimization.